SU-8 mold fabrication station

Create your own master SU-8 molds out of a clean room

Our SU-8 photolithography benchtop station includes everything you need to fabricate molds for microfluidics in your lab with the same resolution and efficiency as in a clean room. Everything to shorter the process way and be quickly autonomous in your microfluidic research.

A Turnkey station to fabricate your SU-8 microfluidic mold

Our SU-8 photolithography station is a turnkey offer, no need to acquire any additional equipment. Basically, only a chemical fume hood and a little working space is required. We adjust the offer, together, to be fine-tuned with your needs.

Benefits

- Reach the same pattern resolution as in a clean room

- Get strong photoresist patterns for numerous future PDMS moldings

- Work with robust processes which enable easy reproducibility

- Fabricate your molds without initial knowledge in microfabrication

- Get the best equipment to ensure your facility a long lifetime

Included

Equipments

- Digital hot plate

- UV Lamp system

- Programmable Spin coater

Accessories & Chemicals

All chemicals (SU-8, SU-8 developper, Omnicoat, Isopropanol, Acetone, etc.) and all lab accessories (micropipette, timer, glassware, parafilm, tweezers, dimaond scraper, wafer, glass slides, petri dishes, disposable cups, stirring rods, scalpels, etc.) are included, in order to provide you the most complete set.

We give you all the product references and providers information to refill your stock.

Support

Standard support pack: We take care of the after sale of all your instruments, we provide you microfabrication process-sheet and tutorials, we provide you 1 year phone assistance to answers any microfabrication questions you could have.

Extended support pack: In addition to standard support pack our R&D team install your equipment directly in your labs, we adapt on site all our microfabrication process to your needs and we train your team until there become ready to fabricate all your microfluidic chips.

Our specialists selected and adapted the best instruments to make them work together with reliable process. You can find here a short description of the equipment. Please don’t hesitate to contact us to have more information and keep in mind that we have several model to fit for the best your needs.

SPIN COATER

This spin coater is compact and packed with advanced features. It works with wafer up to ø150mm and 5″ × 5″ (127mm × 127mm) substrates. This spin coater is perfectly fine-tuned to do controllable and repeatable Su-8 photoresist layer.

A device adapted for Soft-lithography applications

Its compact size with the little panel control attached make the device really movable. The product has been widely use for SU-8 photoresist coating. The hole on the lid enables to do dynamic SU-8 coating. Easily connected to PC via Bluetooth, you can saved and named your recipe.

Major strengths:

-

- Designed specifically for ease-of-use

-

- Simple to program from the operator panel or your PC

-

- Ability to set complex sequence with several accelerations and speeds

-

- Non clogging system for extended lifetime

-

- Low vibration

-

- Speed up to 12000 rpm

- Provided with wafer centering tool

UV LAMP SYSTEM

An unique UV LED exposure and masking system (in option) with available light sources at wavelengths of 365 nm or 385 nm. This is a very compact table-top system capable of exposing a wafer surface area of up to 4 inches in diameter. This automatic UV system is compatible with hard (physical) or soft (proximity) masking contacts, and features variable mask to substrate distance control.

An unique UV LED exposure and masking system (in option) with available light sources at wavelengths of 365 nm or 385 nm. This is a very compact table-top system capable of exposing a wafer surface area of up to 4 inches in diameter. This automatic UV system is compatible with hard (physical) or soft (proximity) masking contacts, and features variable mask to substrate distance control.

A device adapted for Soft-lithography applications

With 2μm resolution, the device is particularly well tuned for soft-lithography applications. The exposure in flash enables to reduce the internal mechanical stress of the photoresist. Its little size enables to install it everywhere you want, especially outside a clean room.

Major strengths:

- Perfectly monochromatic exposure over the wafer surface area (bandwidth lower than 10 nm)

- Cold UV exposure

- Divergence angle of the light < 2°

- Strong power density

- Long LED lifetime: more than 10 000 hours equivalent to 8 – 10 years of use

- User-friendly touch screen interface for exposure cycles programming

- No warm-up time required

- Intuitive control of UV source intensity

- Automated wafer loading and unloading system

- Usable with glass and plastic photomask

- High UV uniformity on 4 inches wafer

- Integrated UV meter

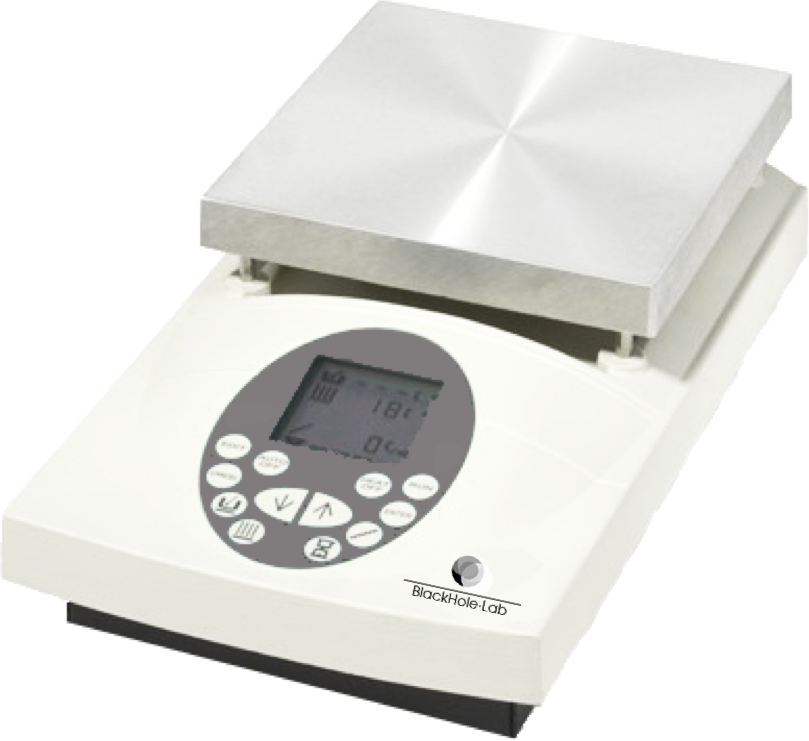

PROGRAMMABLE HOT PLATE

Ensure accurate, homogeneous and stable temperature set points. This digital hotplate device enables to set temperature ramp for heating and cooling down. Make your life easier with its programmable controls which enable to automatize your photolithography process.

Ensure accurate, homogeneous and stable temperature set points. This digital hotplate device enables to set temperature ramp for heating and cooling down. Make your life easier with its programmable controls which enable to automatize your photolithography process.

A device adapted for Soft-lithography applications

Its aluminum top plate and its great heating surface area enables to have a wide enough zone where the temperature is homogeneous for an efficiently bake of SU-8 photoresist on a 4 inches wafer. The temperature ramp enables to reduce the mechanical stress inside the photoresist layer. The programmable tool enables to do long photoresist bakes without staying in front of the device.

Major strenghts:

- Temperature ramp to heat up and cool down.

- High temperature uniformity over 4 inches wafer

- Microprocessor display maintains consistent temperature

- Minimal temperature overshoot

- Automatic timer

- Smoothed aluminium plate for easy photoresist cleaning

AN ADAPTIVE OFFER!

Since each laboratory is different, since each research is unique, we do adapt the offer to be as close as possible of the real need. We discuss together what will be the best efficient facility and thus add or remove equipment, accessories, chemicals…

Do not hesitate to ask one of our technico-commercials to make an assessment of your facility and to advice you on your project.

OPTIONS

We have created basic offers with everything needed to have a complete working set, but some options or some modification can be done to fit better your needs. Please have a look on our product overview lo learn more about the options.

Besides this we gather here a selection of side equipment more suitable for your SU8 mold station.

Air compressor

A fitted air compressor up to 8 bar to replace any gas line of your lab.

A fitted air compressor up to 8 bar to replace any gas line of your lab.

Vacuum pump

A small vacuum pump to replace any vacuum line in your lab to allow degassing and also maintain strongly any substrate on your spin coater.

Developer agitator

To easily develop your thick layer of photoresist you can use this developer tool, it will give you the best shaking during all your development time.

To easily develop your thick layer of photoresist you can use this developer tool, it will give you the best shaking during all your development time.

Optical profiler

If you want to check the thickness of your mold once it’s done. We can advice you this optical profiler.

Easy to use and enough small to fit in your lab bench it’s one of the best ratio quality/price on the market.

Non contractual pictures – BlackHole Lab reserves the right to modify any item without prior notice

For general information

For further information, do not hesitate to contact our team of experts:

contact@blackholelab.com or phone: +33(0).782.831.207