Expand your research thanks to microfluidics!

We can help you using microfluidics to grow up your research and development capacity!

Microfluidics is a miniaturization science that could allow your research to make a leap forward!

But what miniaturization can bring to you?

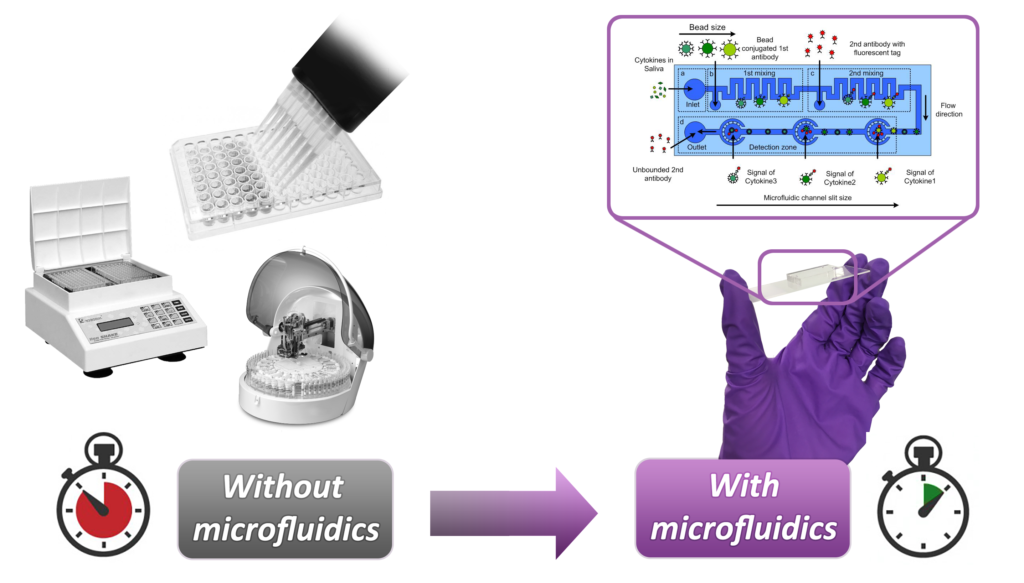

- Small volumes used in microfluidics lead to fast reactions with less reagents

- High surface-to-volume ratio enables to enhance sensitivity

- The easy formation of a laminar flow enables a slow mixing and better control on fluids

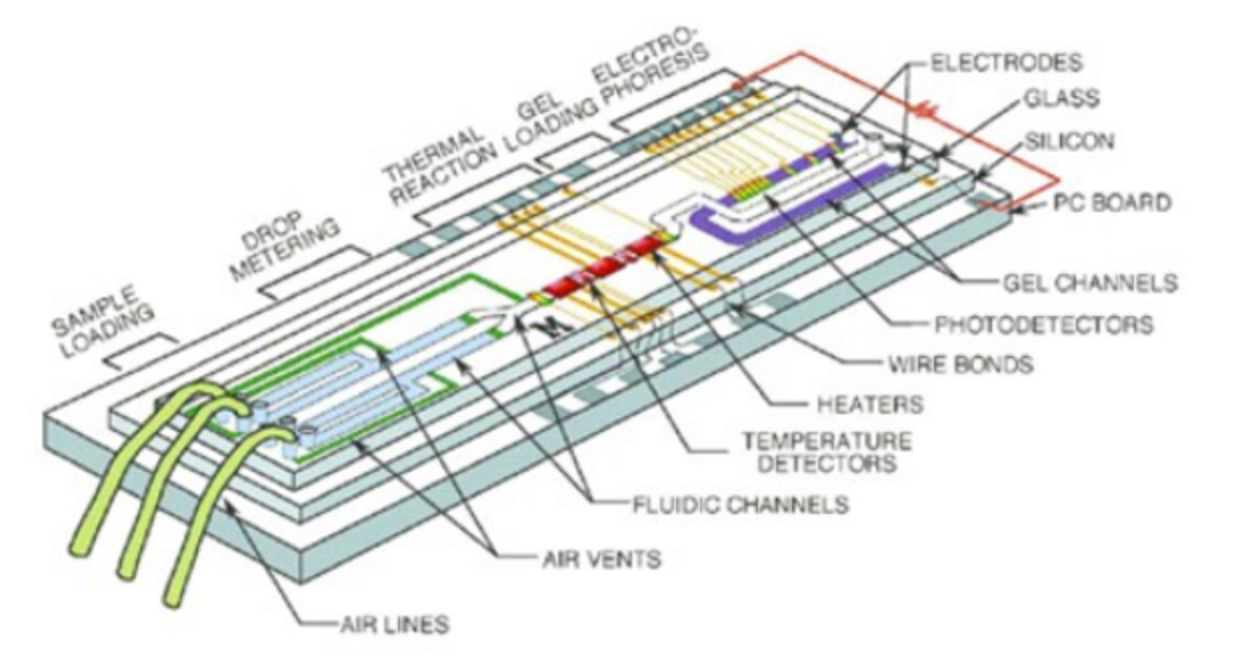

- The small size of the devices allows multiple functions to be integrated

BlackHole Lab offers to help you finding how microfludics could support you in your various research through these five offers and steps:

- Ideation (1 day): An introduction to microfluidics in front of your team followed by an open discussion on the different applications related to your field. Many ideas for research and development emerge from this kind of event!

- Audit (1-2 days on site + written report on specific projects): A visit to your facility and the study of some of your projects will allow us to point out what can be transposed in microfluidics. We will then produce a report detailing what microfluidics can bring to you and which process would allow it (advantages, disadvantages, technological barriers).

- Feasibility study (a kick-off meeting and a theoretical report): Once a project has been identified (during the previous steps or directly by yourself), our feasibility study will be based on in-depth bibliographic research. Supported by a scientific demonstration and bibliographic reference, we will propose a few solutions to realize the project.

- Prototyping and proof of concept (implementation an experimental report): Experimental development of the solution chosen together during the feasibility study The manufacture of one or more devices followed by microfluidics experiments will enable the principle to be validated through tests carried in your facility.

- Scale up and industrialization: Depending on your needs, we can help you get the equipment to continue working on this project yourself. It is also possible to support you towards industrialization thanks to our various partners specializing in the issue.

Microfluidics is a field having a fast growth. Applications became more and more relevant in a lot of science fields, especially for life sciences (biomedical,…). You can find here some examples of applications of microfluidics.

Are you a biologist?

- Cell analysis (culture, separation or behavior)

- Organ-on-a-chip

- DNA sequencing

- PCR amplification

- Evolutionary biology

- Biological assays

- …

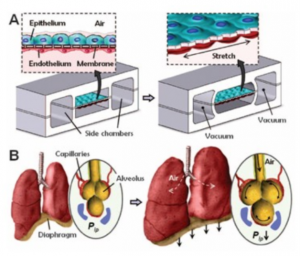

Lung model: Among the parallelization possibilities of microfluidics, organ-on-a-chip is a promissing field. Lung on a chip is becoming a well known model and is based on the use of 2 layers of living tissues with 2 types of cells cultured on opposite sides of a stretchable (to mimic breathing) membrane.

It can predict absorption of airborne nanoparticles and mimic the inflammatory response triggered by microbial pathogens. It can be used to test the effects of environmental toxins, absorption of aerosolized therapeutics, and the safety and efficacy of new drugs. It is expected to become an alternative to animal testing.

Are you a chemist?

- Separation systems (Capillary Electrophoresis, Liquid and Gas chromatography,…)

- Detectors (microelectrodes, Mass Spectrometry, photodiodes,…)

- Droplet generators (Electrospray Ionization)

- Ionization systems (Corona, UV,…)

- Synthesis reactors

- Gradient generators

- Crystallization chips

- …

Drug delivery: Microfluidic systems have been increasingly used for fabrication of drug carriers and recent research activities have been used to study drug delivery (A. Khademhosseini et al.). Microfluidics can bring some transdermal microfluidic devices which could allow an easy and painless delivery of drugs to patient. This science mays enable the delivery of active molecules at cell, tissue and organ level.

Are you a physicist?

- Cooling systems

- Power-Microelectromechanical systems (Power-MEMS): combustion engines, fuel atomizers, fuel cells

- Optofluidics (tunable mirolens arrays, optofluidic microscopes)

- Fluid sensors (rate, viscosity, shear,…)

- …

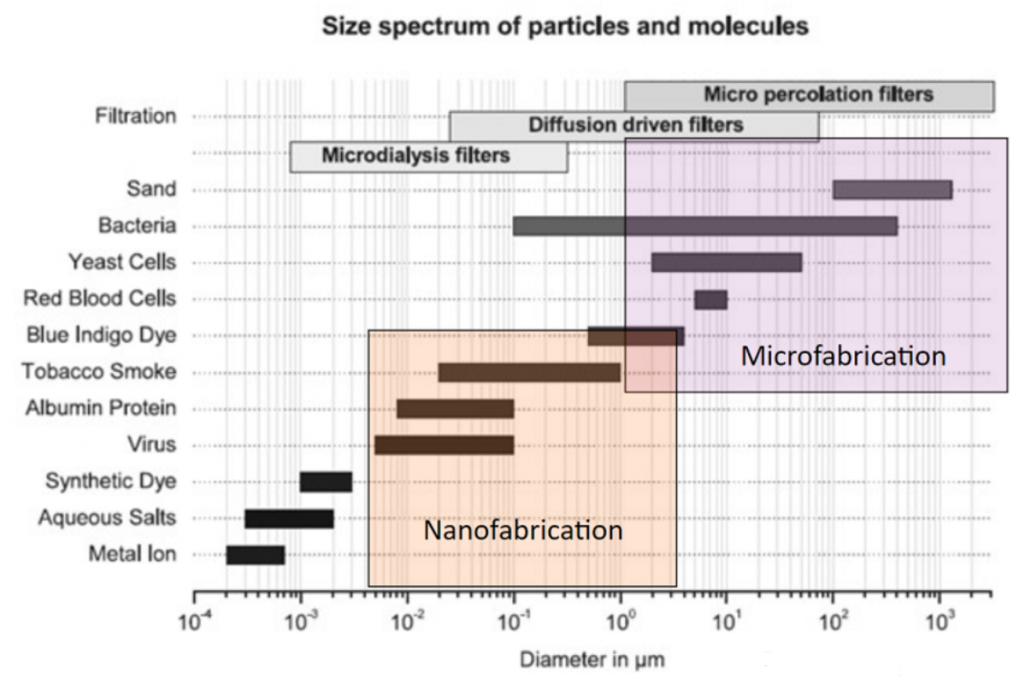

Small size scales & Scalling effects

The micro scale induces unique chemical and physical features that occur in fluids, which allow to have several advantages over conventional “macro”-techniques (for example, surface tension, domination of fluidic resistance,… Micro and nano scales remain dominated by surface effects).

Typical sizes of microfluidics channels: width and height 10 – 100 µm, length 1mm – 1cm.

Typical volumes: 1µL for a microfluidic chip.

Microfluidics structures can be fabricated at roughly the same scale as analytes.

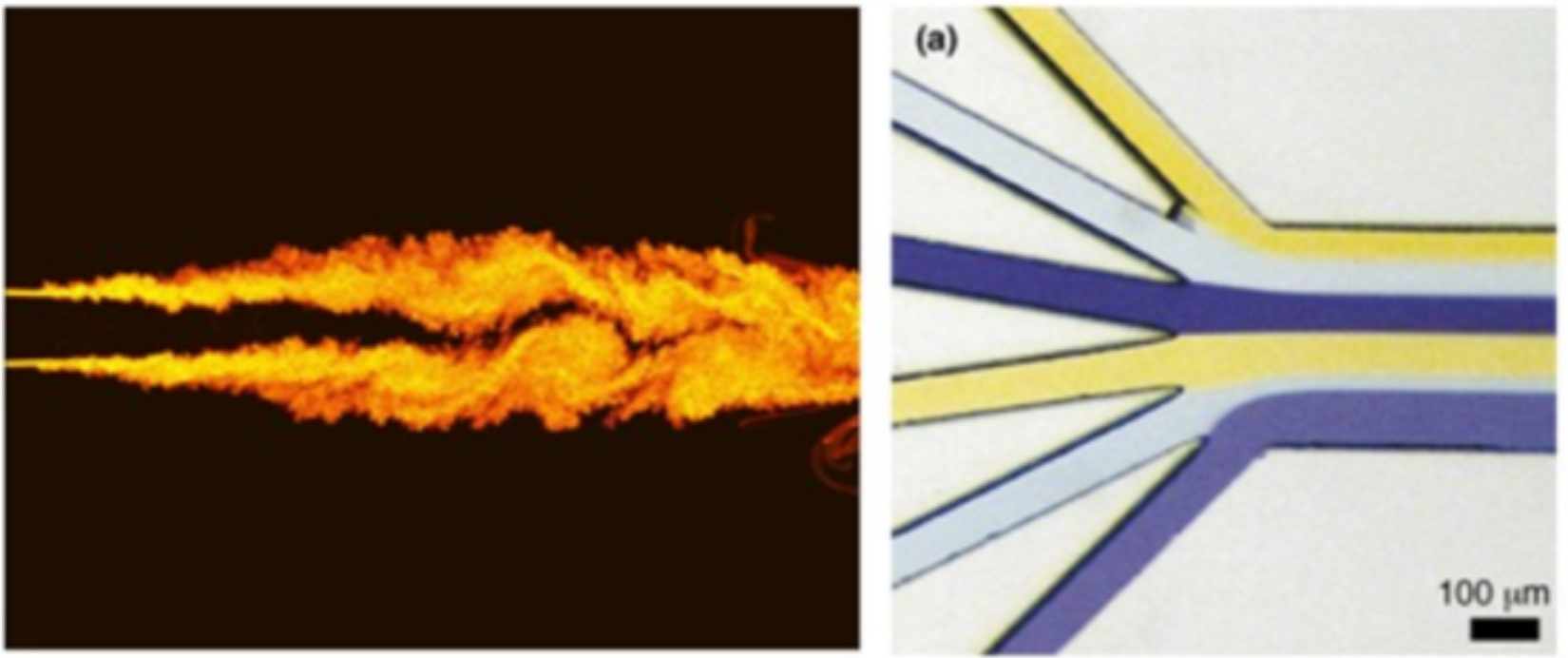

Laminar Flow

One of the properties which is different from the macro scale is Reynolds number for example: with micro scale, it can become very low. It induces the possibility to have several fluids next to each other without any mixing as flow becomes laminar rather that turbulent.

Turbulent (left) vs. Laminar (right) flow

Turbulent (left) vs. Laminar (right) flow

The laminar flow enables to have a slow mixing (in comparison with turbulent flow) by diffusion and to have better control on fluids than with turbulent flow.

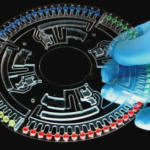

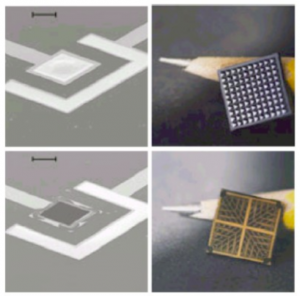

Parallelization and Integration

Thanks to the small size of microfluidic devices, it is possible to have a massive parallelization with several functions in only one chip which allows high-throughput analysis! For example, Lab-on-a-chip gather every functions needed for one application on only one chip! And this comes with a lot of advantages: safer platform for chemical or biological studies (as everything is inside the device without any additional handling), faster analysis and response times and thus better process control …

Thanks to the small size of microfluidic devices, it is possible to have a massive parallelization with several functions in only one chip which allows high-throughput analysis! For example, Lab-on-a-chip gather every functions needed for one application on only one chip! And this comes with a lot of advantages: safer platform for chemical or biological studies (as everything is inside the device without any additional handling), faster analysis and response times and thus better process control …

Non contractual pictures – BlackHole Lab reserves the right to modify any item without prior notice

For general information

For further information, do not hesitate to contact our team of experts:

contact@blackholelab.com or phone: +33(0).782.831.207