PDMS membrane station

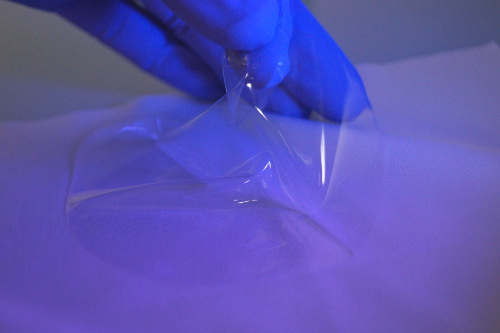

MAKE YOUR OWN PDMS MEMBRANE

Create your PDMS membrane out of a clean room

We offer you all the equipment, accessories and chemicals to fabricate by yourself your own highly reproductible PDMS membranes. Prepare your PDMS, choose the wanted thickness and create your membrane to quickly have fresh PDMS membranes for your experiments. Everything is made in less than one hour!

Our system ensures you:

-

Highly reproducible PDMS membrane

-

Easy manufacturing of PDMS membrane

-

Precise height and wide range of PDMS membrane thickness

Benefits

High precision & wide thickness range: The PDMS membrane kit is based on a low vibration spin coater which enables to precisely control the speed and acceleration up to 12 000 rpm. You can achieve PDMS membrane thickness from ~10µm to 250µm with a high precision.

No PDMS ageing: Get your “fresh” PDMS membrane in 10 minutes and perform reproductible experiments always in the same conditions.

Easy to use: Based on a set of Plug & Play instruments, we have developed processes dedicated to each application. We provide tutorials to enable any researchers to get high standard membrane wihtout initial knowledge.

Get control of your specificities: You can know change the specificities of your PDMS membrane (pore sizes, permeability,…)

Included

Equipments

- Programmable Spin coater

- Hot plate

- Desiccator for PDMS degassing

Accessories & Chemicals

All chemicals (PDMS, Isopropanol, Acetone, etc.) and all lab accessories (glass slides, Petri dishes, disposable cups, stirring rods, scalpels, etc.) are included, in order to provide you the most complete set.

We give you all the product references and providers information to refill your stock.

Support

Standard support pack: We take care of the after sale of all your instruments, we provide you microfabrication process-sheet and tutorials, we provide you 1 year phone assistance to answer any microfabrication question you could have.

Our specialists selected and adapted the best instruments to make them work together with reliable process. You can find here a short description of the equipment. Please don’t hesitate to contact us to have more information and keep in mind that we have several model to fit for the best your needs.

SPIN COATER

This spin coater is compact and packed with advanced features. It works with wafer up to ø150mm and 5″ × 5″ (127mm × 127mm) substrates. This spin coater is perfectly fine-tuned to do controllable and repeatable PDMS membrane.

This spin coater is compact and packed with advanced features. It works with wafer up to ø150mm and 5″ × 5″ (127mm × 127mm) substrates. This spin coater is perfectly fine-tuned to do controllable and repeatable PDMS membrane.

A device adapted for Soft-lithography applications

Its compact size with the little panel control attached make the device really movable. Easily connected to PC via Bluetooth, you can saved and named your recipe. Can be used with SU8 to make mold as such as the PDMS to make membranes.

Major strengths:

- Designed specifically for ease-of-use

- Simple to program from the operator panel or your PC

- Ability to set complex sequence with several accelerations and speeds

- Non clogging system for extended lifetime

- Low vibration

- Speed up to 12000 rpm

- Provided with wafer centering tool

DEGASSING KIT

A degassing kit to remove bubble after PDMS mixing between monomer and curing agent. Composed of a desiccator and a vacuum pump, it’s an easy and simple kit to degas before or after pouring on your mold and can also be used to remove air inside PDMS once your chip is made.

A degassing kit to remove bubble after PDMS mixing between monomer and curing agent. Composed of a desiccator and a vacuum pump, it’s an easy and simple kit to degas before or after pouring on your mold and can also be used to remove air inside PDMS once your chip is made.

Degassing by using a desiccator remains the most used technique because it’s the simplest way and doesn’t need a high investment.

Major strengths:

- Easy to use

- Versatile equipment

- Low cost

HOT PLATE

The PDMS need to be baked to become hard and for membranes, the hot plate appears to be the best solution.

The PDMS need to be baked to become hard and for membranes, the hot plate appears to be the best solution.

What’s more, depending on the process followed you may also have to bake the photoresist. In that case we have selected a simple and efficient hot plate which does the job with the best ration quality/price. This hot plate can’t be used for SU8 photoresist baking but the price allow it to be only dedicated for PDMS membrane application and by the same occasion prevent of any contamination.

Major strenghts:

- Really easy to use.

- Best ratio quality/price.

- Small and light to be installed everywhere.

AN ADAPTIVE OFFER!

Since each laboratory is different, since each research is unique, we do adapt the offer to be as close as possible of the real need. We discuss together what will be the best efficient facility and thus add or remove equipment, accessories, chemicals…

Do not hesitate to ask one of our technico-commercials to make an assessment of your facility and to advice you on your project.

OPTIONS

We have created basic offers with everything needed to have a complete working set, but some options or some modification can be done to fit better your needs.

Besides this we gather here a selection of side equipment more suitable for your PDMS membrane kit.

Air compressor

A fitted air compressor up to 8 bars to replace any gas line of your lab.

A fitted air compressor up to 8 bars to replace any gas line of your lab.

Centrifuge

A smart alternative to degas your PDMS in 2min.

A smart alternative to degas your PDMS in 2min.

Non contractual pictures – BlackHole Lab reserves the right to modify any item without prior notice

For general information

For further information, do not hesitate to contact our team of experts:

contact@blackholelab.com or phone: +33(0).782.831.207